Injection Molding Manufacturing: A Comprehensive Guide

Injection molding manufacturing is a critical process in the field of production, particularly when it comes to fabricating complex parts and components with high precision. This process has become a backbone of many industries, including automotive, consumer goods, and electronics, among others. In this article, we will delve into the various aspects of injection molding manufacturing, its benefits, applications, and its significance in the realm of metal fabricators like deepmould.net.

Understanding Injection Molding Manufacturing

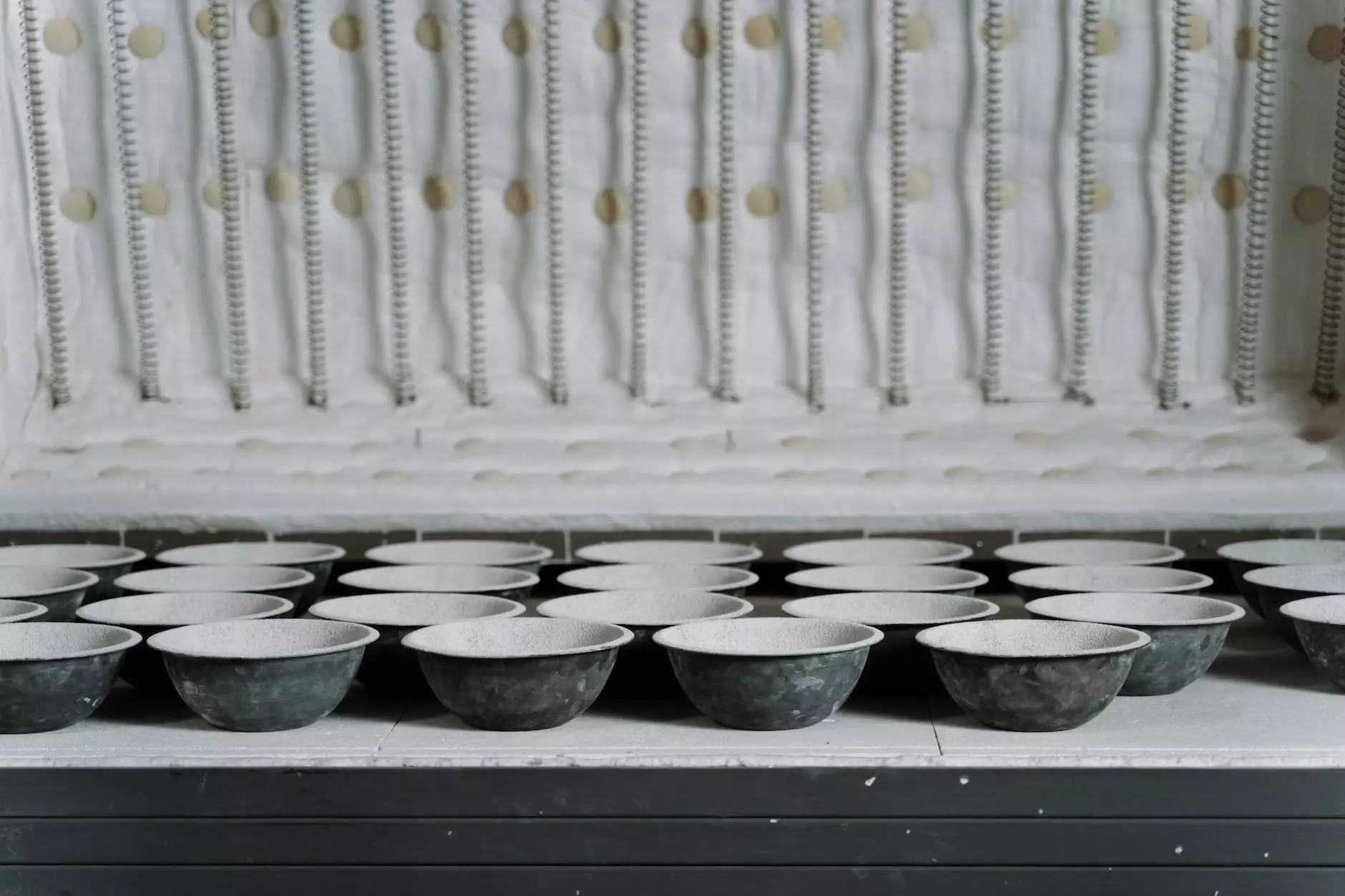

At its core, injection molding is a thermoplastic processing technique where molten material is injected into a mold cavity, allowed to cool and solidify, and then ejected from the mold. This method is predominantly used for producing plastic parts, but it is also applicable in metal fabrication under specific conditions. The process streamlines production and reduces waste, making it an essential technique in the manufacturing toolkit.

The Process of Injection Molding

Injection molding manufacturing comprises several key steps:

- Material Preparation: The process begins with selecting appropriate materials, usually thermoplastics or thermosetting plastics.

- Melting: The raw material is fed into a heated barrel and melted using either heating elements or a combination of heat and mechanical shear.

- Injection: Once molten, the material is injected into the mold at high pressure. The speed and pressure of injection can greatly influence the quality and integrity of the final product.

- Cooling: The injected material is allowed to cool and solidify, taking the shape of the mold.

- Ejection: After cooling, the mold opens, and the finished part is ejected. The mold is then ready for the next cycle.

Advantages of Injection Molding Manufacturing

Injection molding manufacturing offers several notable benefits, making it a preferred choice for many manufacturers:

- High Efficiency: The injection molding process is highly efficient, allowing for mass production of parts in a shorter time frame.

- Design Flexibility: Complex geometries can be achieved with relative ease, enabling designers to create intricate product designs.

- Material Variety: A wide range of materials can be used, including various types of plastics and metals, enhancing material choices for manufacturers.

- Minimal Waste: The precision of injection molding minimizes waste and scrap, which is environmentally friendly and cost-effective.

- Consistent Quality: The ability to produce virtually identical parts contributes to improved consistency in quality and performance across large production runs.

Applications of Injection Molding Manufacturing

The versatility of injection molding manufacturing allows it to be applied across various industries:

Automotive Industry

In the automotive sector, injection molding manufacturing is essential for creating components such as dashboards, paneling, and various internal parts that require durability and precision.

Consumer Products

Many household items, from toys to kitchenware, are produced using injection molding due to the ability to produce designs that meet consumer needs.

Electronics Manufacturing

Electronics rely on injection molding for creating casings, buttons, and connectors, ensuring products are both functional and aesthetically pleasing.

Medical Devices

The medical industry benefits from injection molding by producing components that require sterilization and high levels of precision, critical in devices such as syringes, housings for instruments, and various other medical applications.

Injection Molding in Metal Fabrication

While injection molding is largely associated with thermoplastics, its application in metal fabrication is increasingly gaining traction. Metal injection molding (MIM) combines the advantages of traditional metalworking with the efficiency of injection molding, allowing for the production of high-performance metal parts.

What is Metal Injection Molding?

Metal injection molding is a process that blends fine metal powders with thermoplastic materials to create a feedstock, which is subsequently injected into molds. This method is particularly beneficial for producing intricate, complex shapes that would otherwise be challenging to achieve with traditional metalworking techniques.

Benefits of Metal Injection Molding

Similar to plastic injection molding, MIM offers numerous advantages:

- Complex Geometries: MIM allows for the creation of parts with complex shapes and thin walls that would otherwise be unfeasible with conventional metalworking methods.

- Cost-Effective Mass Production: Once the mold is created, parts can be produced quickly and inexpensively, making it ideal for high-volume manufacturing.

- High Precision: MIM provides a high degree of dimensional accuracy, ensuring parts fit precisely in their application.

- Material Versatility: Wide-ranging materials can be used, including stainless steel, titanium, and various alloys, broadening the scope of applications.

Innovations in Injection Molding

The injection molding manufacturing industry continually evolves, adopting new techniques and technologies to enhance efficiency and quality. Some of the latest trends include:

Automation and Robotics

Many manufacturers are incorporating automation and robotics into their injection molding processes to improve speed and reduce labor costs. Automated systems can monitor production, handle materials, and perform quality checks in real-time.

3D Printing Integration

3D printing is being explored to create mold prototypes, which can drastically reduce the time taken to develop new molds and parts, allowing for quicker iterations and improvements in the design phase.

Choosing the Right Injection Molding Partner

When looking for an injection molding manufacturing partner, particularly in the metal fabricators category like deepmould.net, it is essential to consider several factors:

- Experience: Look for companies with a proven track record in the industry, as their experience can significantly influence the quality of your parts.

- Technology: Ensure that the manufacturer utilizes state-of-the-art technology and modern practices to uphold quality standards.

- Customization Capabilities: The ability to customize molds and processes to meet specific requirements is critical for unique applications.

- Quality Assurance: Confirm that the manufacturer has robust quality control processes in place to ensure that every part meets your specifications.

The Future of Injection Molding Manufacturing

The future of injection molding manufacturing is poised for growth, driven by increasing demand for customized products, sustainable practices, and advancements in technology. As industries evolve, the integration of new materials, environmentally friendly processes, and digital technologies will play a crucial role in shaping the next generation of manufacturing. Companies that stay ahead of these trends, like deepmould.net, will be well-equipped to meet the challenges of a dynamic market.

Conclusion

In summary, injection molding manufacturing is a profound process that has revolutionized the way products are made across various industries. Its efficiency, precision, and versatility make it an indispensable method for manufacturers today. As the landscape of manufacturing continues to change, embracing innovations and advancements in this space will ensure that companies remain competitive and can deliver high-quality products to their customers. Whether you are in need of plastic components or high-performance metal parts, understanding the ins and outs of injection molding can help you make informed decisions in your manufacturing journey.